The high heat riser sleeve, characterized by its non-fluorine content, high heat generation, high shrinkage efficiency, high compressive strength, and maximization of casting yield, when used in conjunction with our patented metal cuttable pieces and accompanying positioning guide rods, offers simple and convenient operation. Moreover, the contact area between the mold flash sleeve and the casting is minimal, making it easy to remove, suitable for shrinkage in high-pressure wet sand molding lines.

0536-6427866

0536-6427866

Shandong Yongchuang Material Technology Co., Ltd

Shandong Yongchuang Material Technology Co., Ltd

Product features

The shrinkage efficiency is high and the compressive strength is high

The contact area with the casting is small, which is suitable for the supplementary operation of isolated thermal joints, which is convenient to remove and reduce the cost of post-processing

Maximum output rate, suitable for high pressure molding line of chime sand

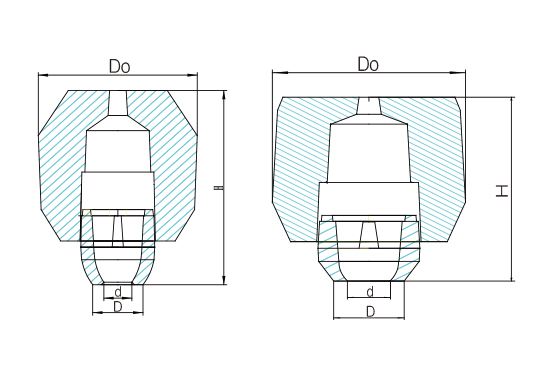

Specifications and models

(Note: Non-standard products can be produced according to different customer requirements)

| Type | Effective Modulus(cm) | Dimensions(mm) | Volume(cm³) | |||

|---|---|---|---|---|---|---|

| D | d | Do | H | |||

| GM10 | 1.0 | 25 | 14 | 56 | 107 | 25 |

| GM12 | 1.2 | 27 | 16.5 | 62.5 | 95 | 50 |

| GM14 | 1.4 | 27 | 16.5 | 70 | 130 | 65 |

| GM17 | 1.7 | 27 | 16.5 | 75 | 140 | 75 |

| GM19 | 1.9 | 27 | 16.5 | 104 | 146 | 95 |

| GM23 | 2.3 | 36 | 20 | 114 | 155 | 138 |

| GM30 | 3.0 | 36 | 20 | 133 | 175 | 183 |

| GM35 | 3.5 | 50 | 32 | 146 | 195 | 390 |